Client: Microchip Technology

Situation

Every year Microchip Technology Inc. (Microchip) increases the complexity of its manufacturing: smaller features, more layers, less contamination. Understanding—systemic, big-picture understanding—is critical to Microchip’s short and long-term success, yet there were only two ways for engineers, technicians, and specialists to get a big picture of the manufacturing process.

- They could mine the knowledge from their colleagues during compressed meetings or on a rush break: this activity is inefficient, sporadic, and unguided.

- They could review the VHS videotapes of a Process Flow Class last updated in 2003.

Solution

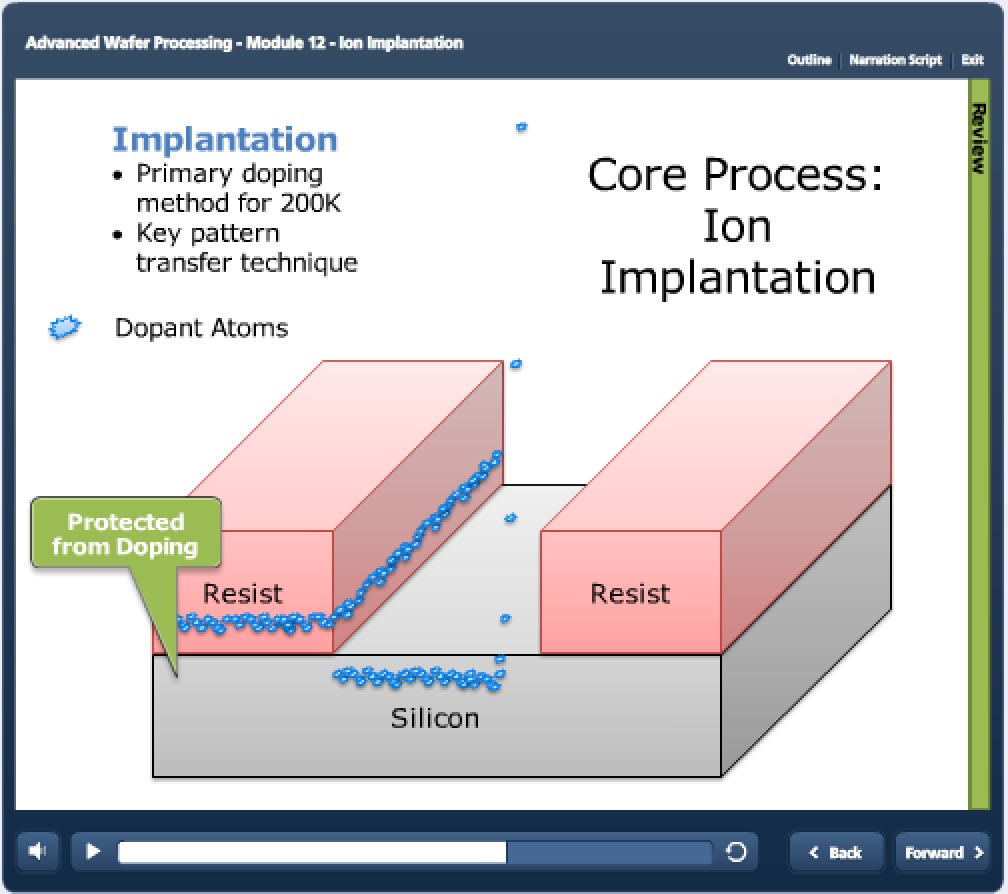

Steaming Kettle developed Advanced Wafer Processing, an interactive, visual, self-paced, web-based training for Microchip’s engineers, technicians, and specialists to advance their technical skills.

At the same time, the courseware gave supervisors a method of tracking the learning process and Microchip clear feedback to maximize returns on training investments.

Key Accomplishments

Comprehensive technology training: Steaming Kettle collaborated with a core group of twelve Subject Matter Experts (SMEs), developing a suite of forty-four self-paced courseware modules. The modules fall into three major areas:

- Science fundamental to semiconductor manufacturing

- Semiconductor manufacturing technologies, their challenges and limitations

- Detailed manufacturing process flow

Broad appeal and technical satisfaction: rapid, accurate audience assessment and effective implementation of adult learning theory were core to achieving a very difficult balance: meeting the technical needs of learners in a way that had them excited to start the next module. Core design features included:

- Respecting the learner’s native intelligence

- Letting users pursue their technical interests

- Allowing them to master material a rate they chose

The way in which the learner’s eye, ear, and hands are synchronized during a session is also critical to the courseware’s effectiveness. Every courseware module is extensively animated, coordinating the visual elements with over 1,400 minutes of audio recording. Users are never overwhelmed with the sudden appearance of a complex system or issue. Instead, complex ideas are built up over time, with the user interaction triggering the next layer of detail at a pace that’s appropriate for them.

Deployment and tracking ease: the Advanced Wafer Processing courseware was SCORM-compliant, which allowed all the user tracking and reporting features of Microchip’s existing Learning Management System (LMS) to function from the release of the very first module. The paths individual learners took within modules was recorded, as were their answers to evaluation questions and the number of attempts needed to get the correct answers. Since the modules are offered a la carte, the LMS also tracked which modules a user had completed, and on what date they were completed.

Business Impacts

With the technical content developed and deployed in three major phases, the Advanced Wafer Processing curriculum was wildly successful from the release of the first phase.

Originally targeted at U.S. manufacturing operations, engineering groups beyond manufacturing have voluntarily adopted the training. Also, manufacturing operations worldwide have voluntarily adopted the training.

At the time the third phase was released, 1900 employees had begun one or more modules, 1300 employees had completed at least one module, and the cost of a training completion was $55 per person and dropping.